SEMICONDUCTOR METROLOGY APPLICATIONS

Semiconductors are the backbone of modern life.

Found in everything, from smartphones and electric vehicles to AI systems and industrial automation, they power over 90% of all

electronic devices.

As chip complexity increases and miniaturization continues, semiconductor metrology becomes essential to ensure high yield, quality, and reliability in production.

What is semiconductor metrology?

Semiconductor metrology is the science of measuring semiconductors’ physical properties, structures, and performance throughout their fabrication workflow. Metrology enables tight process control at nanometric scales, from wafer metrology and thickness measurement in semiconductor processing to final chip testing.

As devices become smaller and more complex, even the tiniest structural defects or dimensional variations can compromise performance, making

precise metrology an essential part of semiconductor manufacturing.

Semiconductor metrology is the science of measuring semiconductors’ physical properties, structures, and performance throughout their fabrication workflow. Metrology enables tight process control at nanometric scales, from wafer metrology and thickness measurement in semiconductor processing to final chip testing.

As devices become smaller and more complex, even the tiniest structural defects or dimensional variations can compromise performance, making

precise metrology an essential part of semiconductor manufacturing.

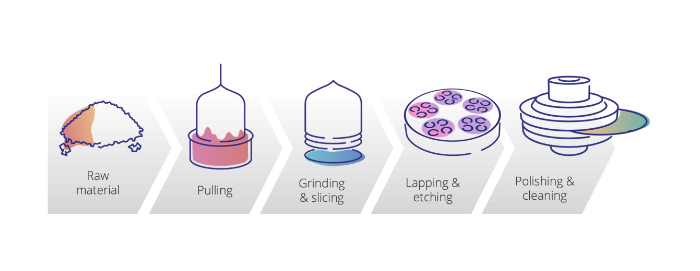

Semiconductor manufacturing workflow

Semiconductor manufacturing is one of the world’s most advanced and precise engineering processes. At its core, it transforms raw materials into highly complex microchips that power modern technology. Metrology is essential across the entire chip fabrication process.

Purified silicon is converted into wafers, which are the foundation for all transistor structures and the building blocks of semiconductor chip manufacturing.

Key wafer metrology needs are:

- Flatness

- Coplanarity

- Defects

- Roughness

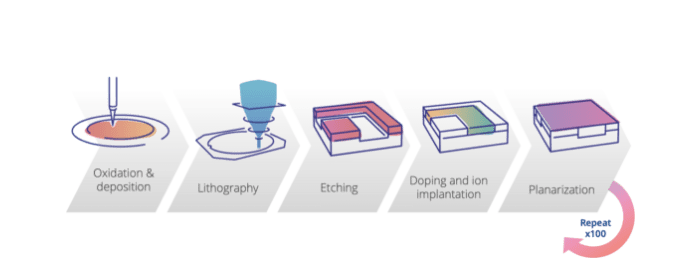

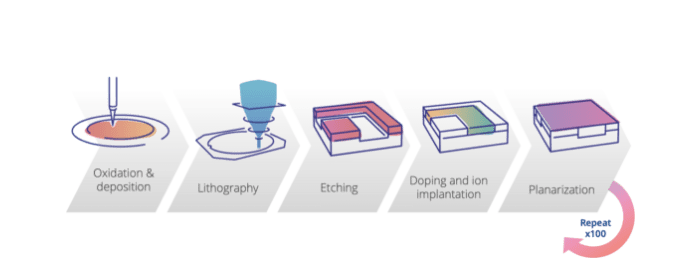

The wafer undergoes hundreds or thousands of high-precision steps to create the intricate transistor structures that define the chip’s functionality. In production metrology, detecting defects and controlling structural parameters is critical to creating transistor architectures.

- Deposition thickness

- Etch depth & profile

- Mask critical dimensions

- Defects

- CMP pads & conditioner

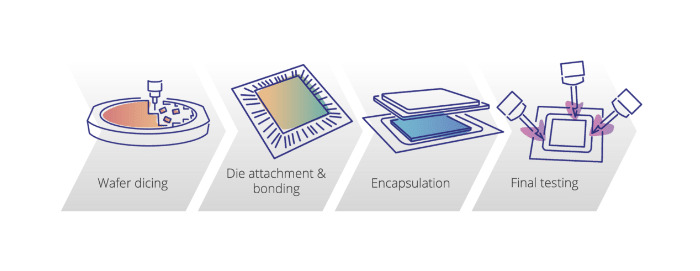

The wafer is cut into individual dies, which are then packaged and tested to ensure proper protection, reliable electrical connections, and expected performance. Using advanced metrology tools for the semiconductor back-end processing, like:

- Wafer cutting

- Die adhesion and mounting

- Component coplanarity

- Testing marks

- Labeling and marking

Applications

WAFER FABRICATION

Third-generation materials

These materials can withstand higher temperatures, voltages, and radiation levels, making them essential for advanced metrology manufacturing applications such as renewable energy and high-power devices.

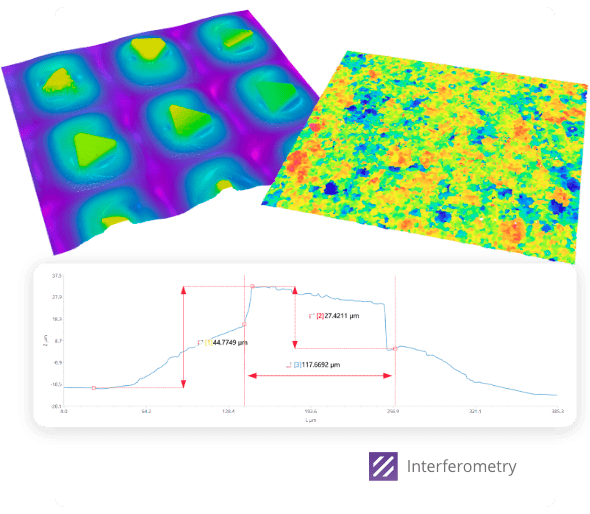

DIAMOND

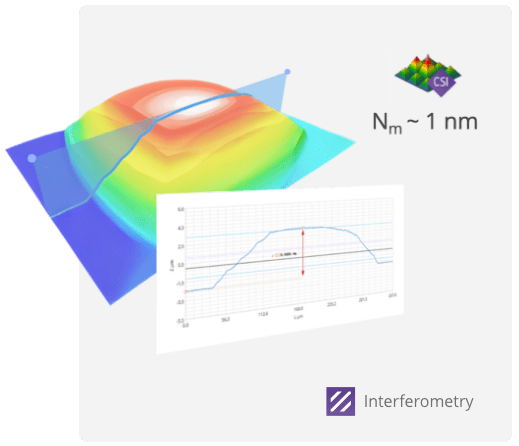

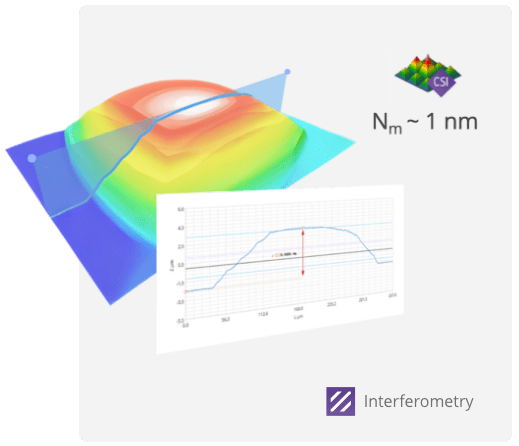

Diamonds are closely monitored for growth patterns that are critical to their performance. Morphological measurements, essential for assessing their structure, target precise dimensions, often down to the micrometer or nanometer scale. Here, Interferometry technology proves invaluable, it excels at capturing details in surfaces with high aspect ratios and steep slopes, ensuring accuracy and minimizing measurement errors.

Diamonds are closely monitored for growth patterns that are critical to their performance. Morphological measurements, essential for assessing their structure, target precise dimensions, often down to the micrometer or nanometer scale. Here, Interferometry technology proves invaluable, it excels at capturing details in surfaces with high aspect ratios and steep slopes, ensuring accuracy and minimizing measurement errors.

SILICON CARBIDE (SiC)

SiC wafers produced through Chemical Vapor Deposition (CVD) undergo topographical evaluation to assess the uniformity of lattice growth. For this purpose, Interferometry technology is especially effective, delivering high precision on ultra-smooth surfaces with varying heights. This approach provides essential insights that support quality control in SiC wafer production.

SiC wafers produced through Chemical Vapor Deposition (CVD) undergo topographical evaluation to assess the uniformity of lattice growth. For this purpose, Interferometry technology is especially effective, delivering high precision on ultra-smooth surfaces with varying heights. This approach provides essential insights that support quality control in SiC wafer production.

PEROVSKITE

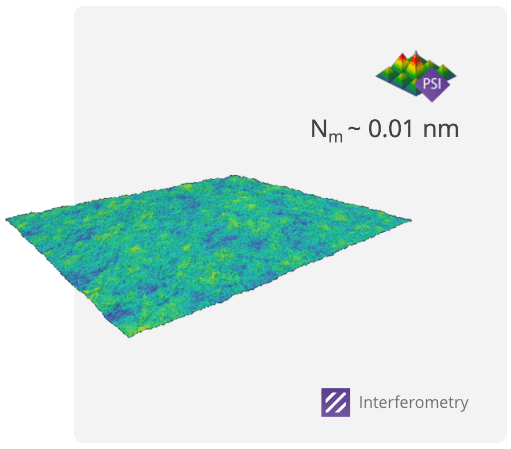

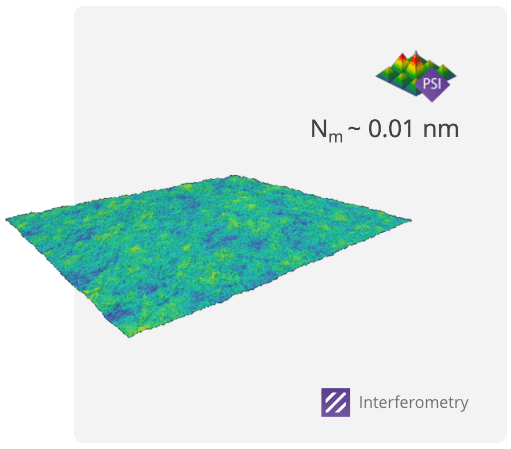

The surface roughness of perovskites is closely linked to the manufacturing quality. For this exceptionally smooth material, Interferometry is the preferred measurement technique due to its low measurement noise, reaching as low as 0.01 nm.

The surface roughness of perovskites is closely linked to the manufacturing quality. For this exceptionally smooth material,

Interferometry is the preferred measurement technique due to its low measurement noise, reaching as low as 0.01 nm.

FRONT-END PROCESSING

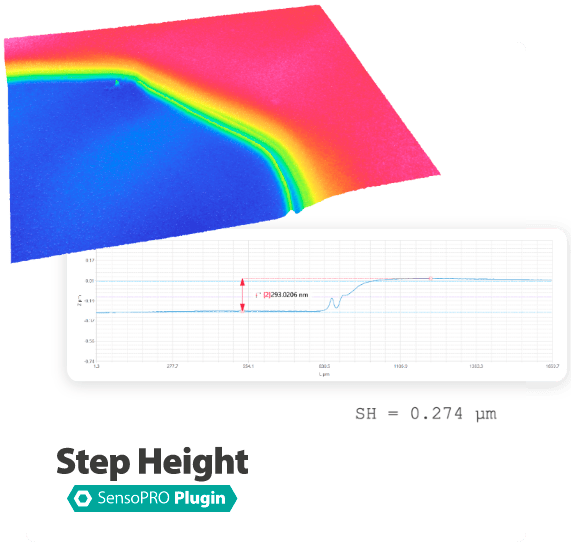

Film thickness

One of the most critical parameters in semiconductor processing. Accurate film thickness control ensures optimal transistor performance and electrical isolation. Sensofar’s S neox can accurately measure film thicknesses from 50 nm to several millimeters using Spectroscopic Reflectometry and Interferometry techniques.

Interferometry is the best technique for measuring through micron-thick films and step-height-like structures down to the nanometer level, while Spectroscopic Reflectometry offers a fast, non-contact, and highly accurate method for measuring through thin films ranging from 50 nm to 1.5 µm.

One of the most critical parameters in semiconductor processing. Accurate film thickness control ensures optimal transistor performance and electrical isolation. Sensofar’s S neox can accurately measure film thicknesses from 50 nm to several millimeters using Spectroscopic Reflectometry and Interferometry techniques.

Interferometry is the best technique for measuring through micron-thick films and step-height-like structures down to the nanometer level, while Spectroscopic Reflectometry offers a fast, non-contact, and highly accurate method for measuring through thin films ranging from 50 nm to 1.5 µm.

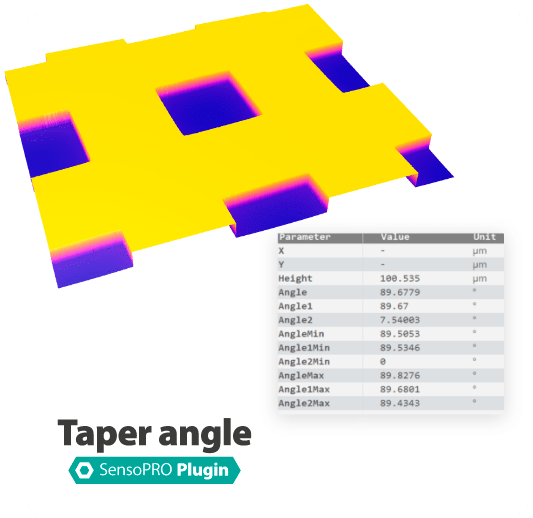

FRONT-END PROCESSING

Etch profile

Etching is a key process in semiconductor manufacturing, where material is selectively removed from the wafer to shape circuit features. Accurate profiling is essential to maintain taper angles and feature integrity. 3D optical profilers provide a non-contact, high-resolution solution for monitoring etching quality by accurately measuring etch depth, width, and overall etch profiles.

Etching is a key process in semiconductor manufacturing, where material is selectively removed from the wafer to shape circuit features. Accurate profiling is essential to maintain taper angles and feature integrity. 3D optical profilers provide a non-contact, high-resolution solution for monitoring etching quality by accurately measuring etch depth, width, and overall etch profiles.

FRONT-END PROCESSING

CMP pad & conditioner

Chemical Mechanical Planarization (CMP) smooths and flattens the wafer surface to achieve uniform thickness, a key requirement in semiconductor measurement and metrology manufacturing. Sensofar’s S mart 2 has demonstrated that CMP pads are largely under-utilized and often discarded, with more than half of the useful lifetime remaining. Check out this case study for a more detailed explanation of the process.

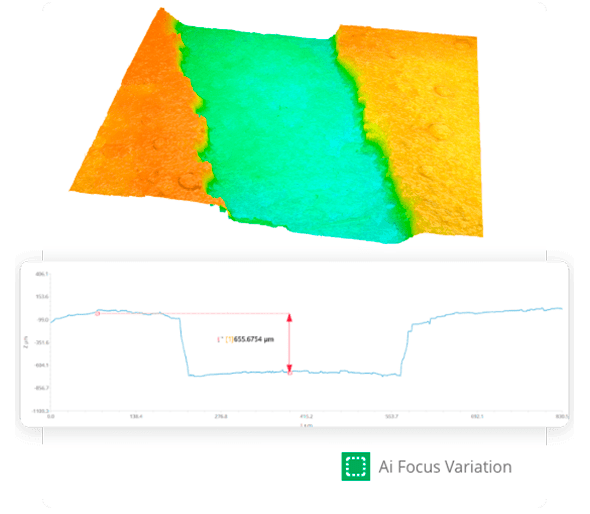

BACK-END PROCESSES

Wafer cutting

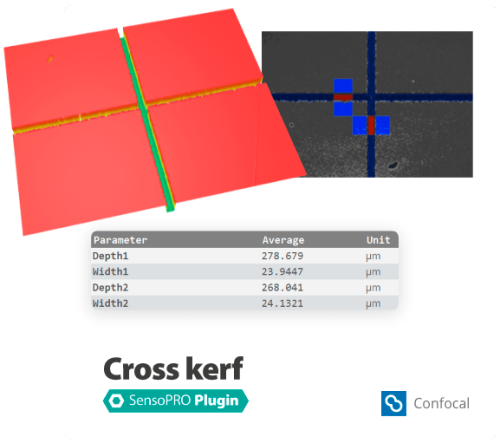

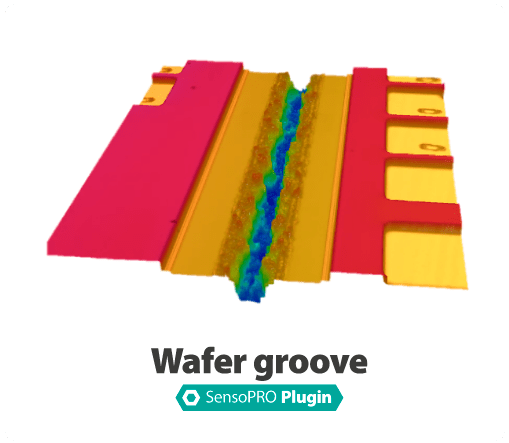

Typically performed in two steps (slotting and cutting) to prevent edge chipping. Accurate metrology ensures process efficiency and die quality. Plugins like Cross kerf and the Wafer groove line series deliver pass and fail reports based on the critical parameters to determine whether the die is approved for the second cut.

BACK-END PROCESSES

Bump inspection

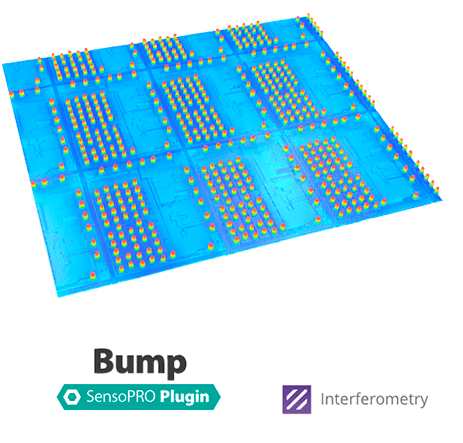

Flip-chip bonding relies on precisely formed bumps for signal integrity and heat dissipation, making accurate semiconductor measurement and metrology manufacturing crucial to control bump height, shape, and coplanarity.

SensoPRO features a dedicated Bump plugin that can detect all bumps in a measurement and determine its key critical parameters for automatic pass/fail reporting.

Flip-chip bonding relies on precisely formed bumps for signal integrity and heat dissipation, making accurate semiconductor measurement and metrology manufacturing crucial to control bump height, shape, and coplanarity.

SensoPRO features a dedicated Bump plugin that can detect all bumps in a measurement and determine its key critical parameters for automatic pass/fail reporting.

Recent research published in MDPI’s Materials journal highlights how 3D optical inspection is becoming essential for detecting packaging defects in high-density interconnects, providing rapid and non-invasive feedback in real time.

As devices grow smaller and more powerful, the need for precise and scalable metrology only grows. Recent studies, such as one published in Nature, underline that achieving consistent quality requires sub-nanometer precision, reinforcing the industry’s move toward advanced, hybrid optical systems.

Your semiconductor metrology expert

As devices grow smaller and more powerful, the need for precise and scalable metrology only grows. Whether you’re exploring the definition of wafer in semiconductor, looking for semiconductor metrology equipment, or seeking a trusted provider of metrology in the semiconductor industry, Sensofar is here to help you stay ahead.

Let’s shape the future of microelectronics, one nanometer at a time.

Your semiconductor metrology expert

As devices grow smaller and more powerful, the need for precise and scalable metrology only grows. Whether you’re exploring the definition of wafer in semiconductor, looking for semiconductor metrology equipment, or seeking a trusted provider of metrology in the semiconductor industry, Sensofar is here to help you stay ahead.

Let’s shape the future of microelectronics, one nanometer at a time.