The new S neox optical profilometer outperforms existing optical 3D profiling microscopes in terms of performance, functionality, efficiency and design, providing Sensofar with a class-leading areal measurement system.

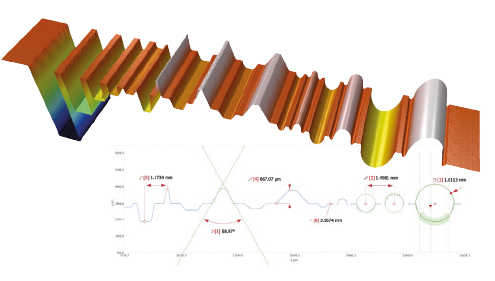

Faster than ever

Everything is faster than before with new smart and unique algorithms and a new camera. Data acquisition is taken at 180 fps. Standard measurement acquisition is 5X faster than before. Making the S neox optical profilometer, the fastest areal measurement system in the market.

Easy-to-use

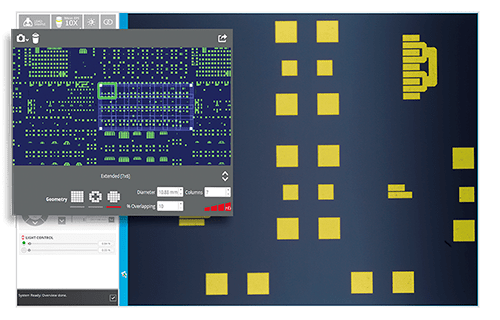

Sensofar is continuously working to provide the most incredible experience to our customers. With the fifth generation of the S neox systems, the goal has been to make it easy to use, intuitive and faster. Even if you are beginner user, the system can be managed with just one click. Software modules have been created to adapt the system to the user requirements.

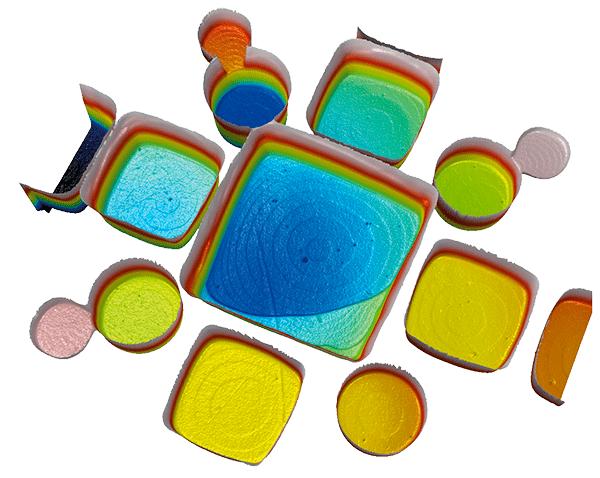

Versatile system

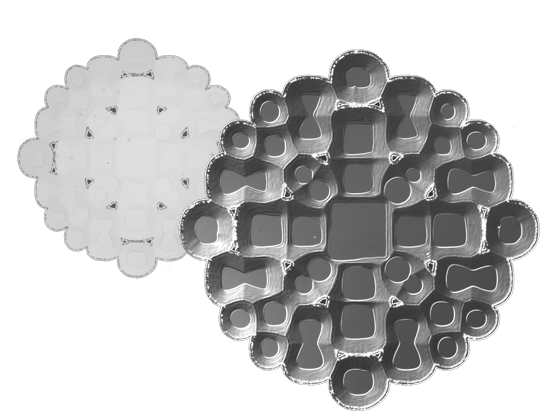

Quality Control

Quality Control

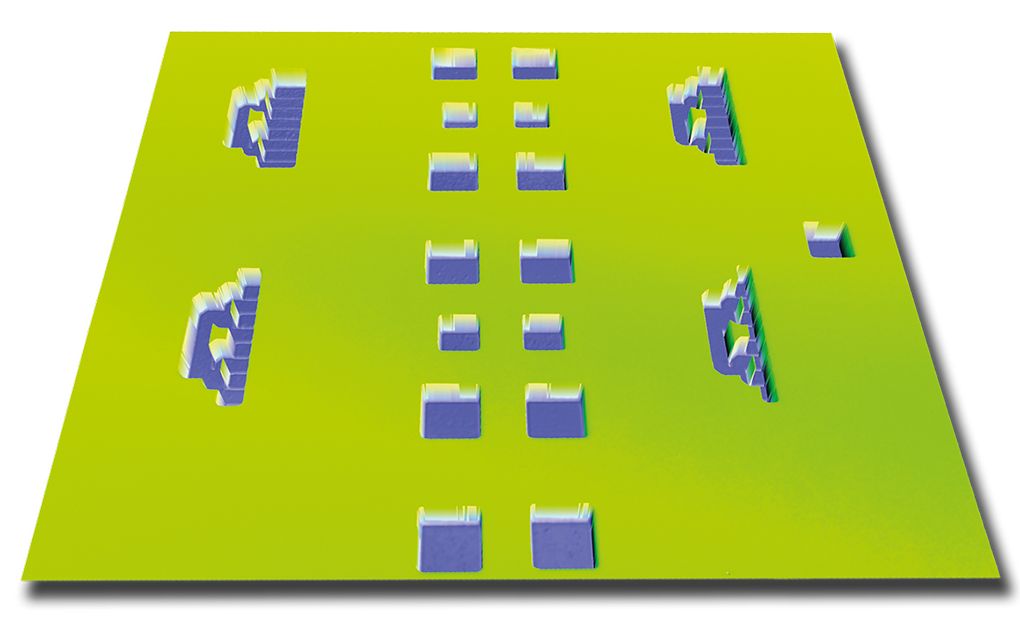

Automated modules have been created

to facilitate all QC procedures. Ranging

from operator access rights control, recipes,

compatibility to barcode/QR readers, and

customized plugins from our proprietary

SensoPRO software to generate pass/fail

reports. Our optimized solutions are able

to work in Quality Control environments

due to their flexibility and easy-to-use interface,

which can be programmed to work 24/7.

Surface finish measures have never been so easy.

Research & Development

Research & Development

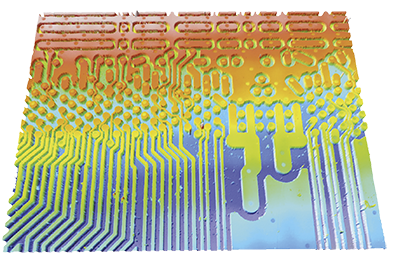

With Sensofar’s 3-in-1 approach –a single

click in SensoSCAN switches the system to

the best technique for the task at hand. The

three measurement techniques found in the

S neox sensor head –Confocal, Interferometry,

Ai Focus Variation– each contribute critically

to the versatility of the system and help to

minimize undesirable compromises in the

data acquisition. The S neox optical profilometer

is ideal for all lab environments,

without limitations.

Quality Control

Quality Control

Automated modules have been created

to facilitate all QC procedures. Ranging

from operator access rights control, recipes,

compatibility to barcode/QR readers, and

customized plugins from our proprietary

SensoPRO software to generate pass/fail

reports. Our optimized solutions are able

to work in QC environments due to their

flexibility and easy-to-use interface, which

can be programmed to work 24/7.

Surface finish measures have never been so easy.

Research & Development

Research & Development

With Sensofar’s 3-in-1 approach –a single

click in SensoSCAN switches the system to

the best technique for the task at hand. The

three measurement techniques found in the

S neox sensor head –Confocal, Interferometry,

Ai Focus Variation– each contribute critically

to the versatility of the system and help to

minimize undesirable compromises in the

data acquisition. The S neox optical profilometer

is ideal for all lab environments,

without limitations.

4-in-1 technologies

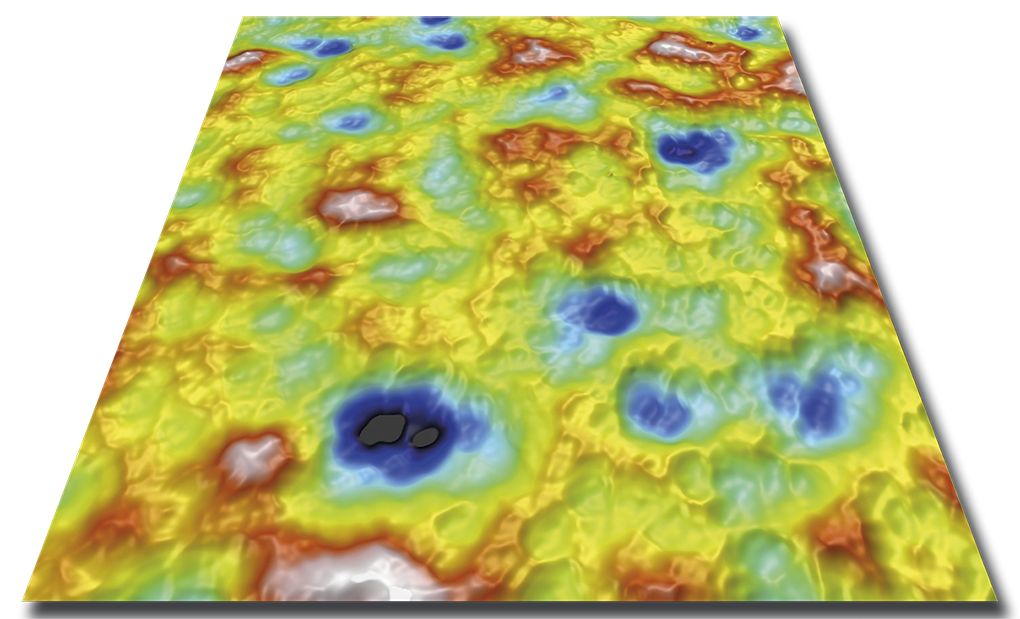

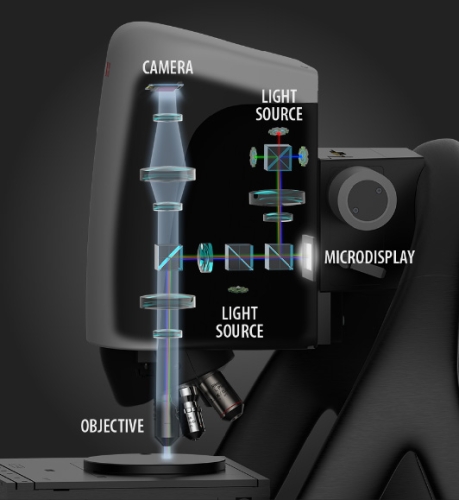

Ai Focus Variation

Active illumination Focus Variation vertically scans either optics (with very low depth-of-field) or the sample to obtain a continuous set of images of the surface. An algorithm determines which points in each frame are in focus, and an entire image is built up using all in-focus points from all frames. It has been improved with the use of active illumination to get more reliable focus location even on optically smooth surfaces.

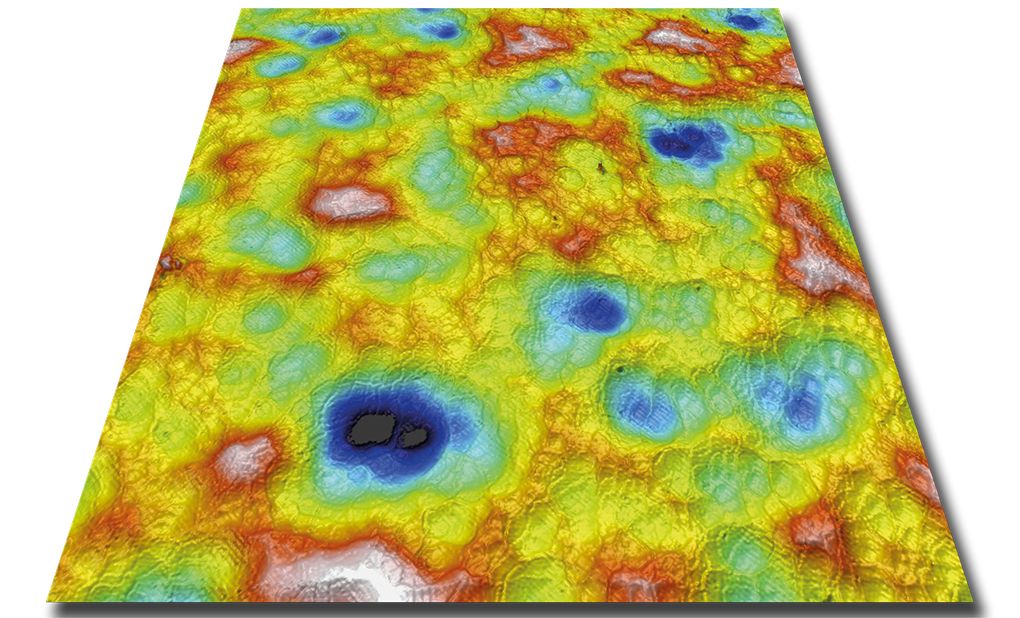

Confocal

The imaging technique included by the Confocal microscopes, utilizes an aperture at the confocal plane of the objective. Out-of-focus light is thus prevented from entering the imaging system and only the in-focus plane on the sample is captured. 2D profiles and 3D surface images can be captured by scanning the aperture mechanically or digitally.

Interferometry

Optical Interferometry makes use of the optical path difference between light reflected in the two arms of the interferometer (reference and sample) to yield an spatial interference pattern (interferograms) that contains information on the surface topology of the sample. Various variations of the approach can be used for particular applications.

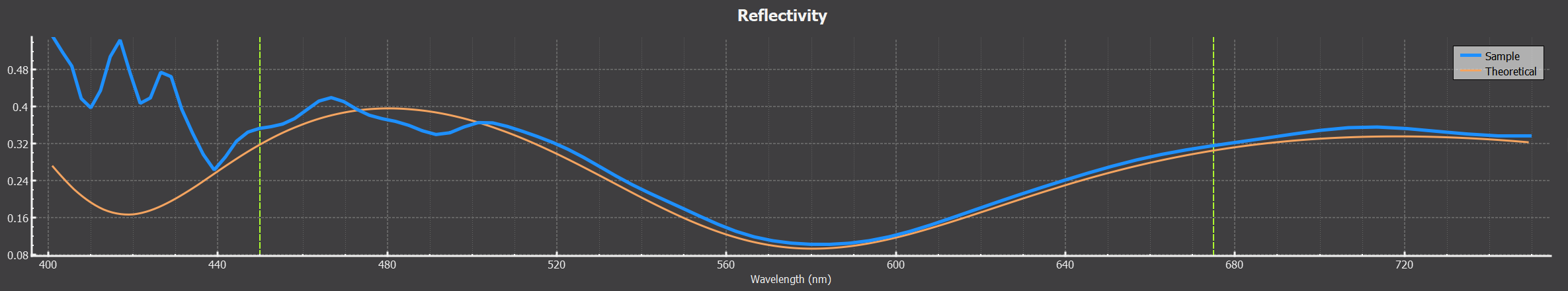

Thin film

Thin film measurement technique measures the thickness of optically transparent layers quickly, accurately, non-destructively and requires no sample preparation. The profilometer acquires the reflectance spectrum of the sample in the visible range, and is compared with a simulated spectra calculated by the software, with layer thickness modification until the best fit is found. Transparent films from 50 nm to 1.5 μm can be measured in less than one second. Sample evaluation spot diameter is dependent on the objective magnification which can be as low as 0.5 μm and up to 40 μm.

Improving performance using a LED

The advantages of using a LED over a laser are vast. LEDs avoid interference patterns and scattering typical of laser light sources. LEDs illuminate an area, rather than a single spot, yielding faster measurement. The estimated lifetime of an LED is about 50.000 h (25 times better than a laser). Finally, they offer great versatility, allowing different wavelengths to be used depending on sample requirements.

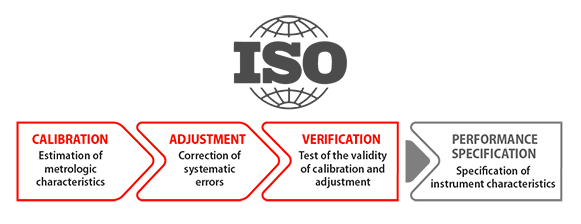

System validation package

Every S neox is manufactured to deliver accurate and traceable measurements. Systems are calibrated using traceable standards following the ISO 25178 standard part 700 and part 600 for: Z amplification factor, XY lateral dimensions, flatness deviation, system noise as well as parcentricity and parfocality. Any metrology instrument must fulfill it before providing any result.

Every S neox is calibrated to estimate the

metrological characteristics using a traceable calibration standard, adjusted to correct systematic errors and verified to match the calibrated value. Finally, the performance specifications are checked, and the instrument characteristics, such as accuracy, and repeatability are provided with the system.

High resolution

Vertical resolution is limited by the instrument noise, which is fixed for Interferometry, but dependent of the numerical aperture for Confocal. Sensofar proprietary algorithms deliver nanometer level system noise for any measurements technique at the highest possible lateral resolution for an optical instrument.

The topography shown is a subnanometer (0.3 nm) atomic layer. Courtesy of PTB.

DIC observation

Differential Interference Contrast (DIC) is used to emphasize very small height features that has no contrast in normal observation. With the use of a Nomarski prism, an interferential image is created resolving sub-nanometer scale structures not visible in brightfield or confocal images.