NON-CONTACT 3D SURFACE METROLOGY

Experience true innovation

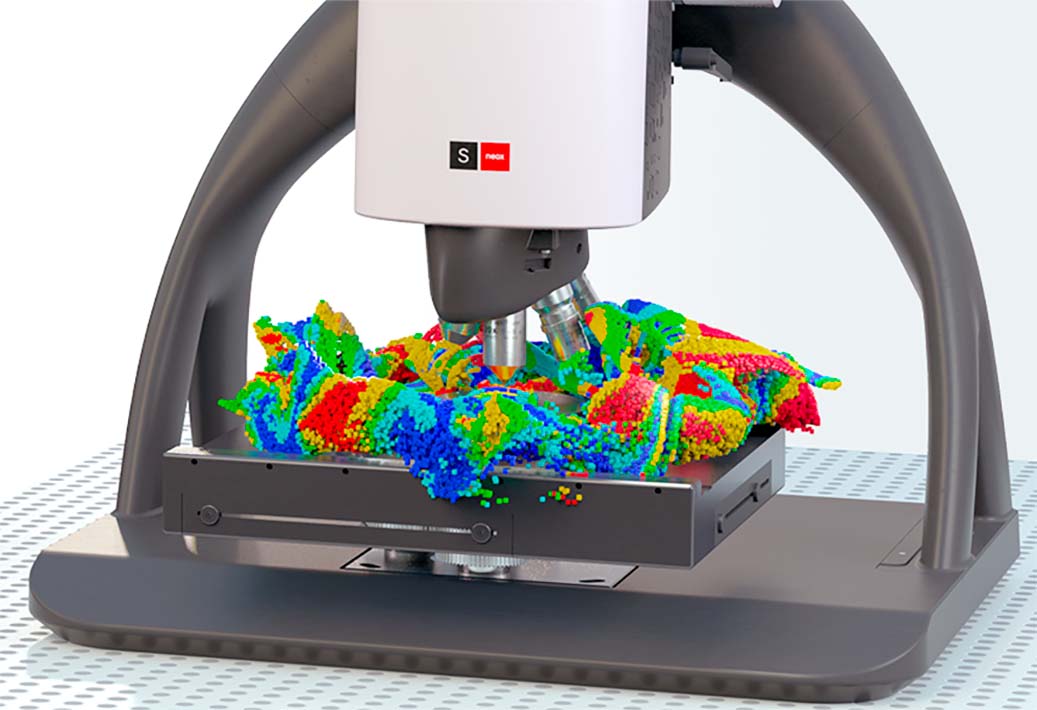

3D surface metrology is the measurement and characterization of micro- and nano-scale features on natural or manufactured surfaces.

This can be achieved very efficiently by capturing the 3D spatial coordinates of points on a surface using a non-destructive optical technique.

Sensofar Metrology designs and manufactures non-contact 3D surface profilers and integrable solutions to provide you with a tool that increases the quality of your products.

NON-CONTACT 3D SURFACE METROLOGY

Experience true innovation

3D surface metrology is the measurement and characterization of micro- and nano-scale features on natural or manufactured surfaces.

This can be achieved very efficiently by capturing the 3D spatial coordinates of points on a surface using a non-destructive optical technique.

We design and manufacture non-contact 3D surface profilers and integrable solutions to provide you with a tool that increases the quality of your products.

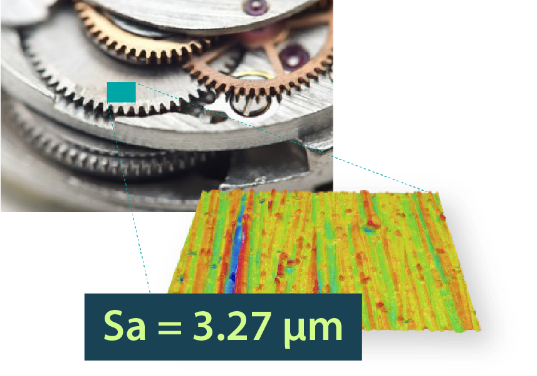

SURFACE TEXTURE

Leading with ISO 25178

Sensofar brings leading expertise in surface texture measurement, designing precise, reliable tools that meet ISO 25178 standards. From research to manufacturing, our solutions ensure consistent, high-quality results in 3D surface characterization.

Sensofar brings leading expertise in surface texture measurement, designing precise, reliable tools that meet ISO 25178 standards. From research to manufacturing, our solutions ensure consistent, high-quality results in 3D surface characterization.

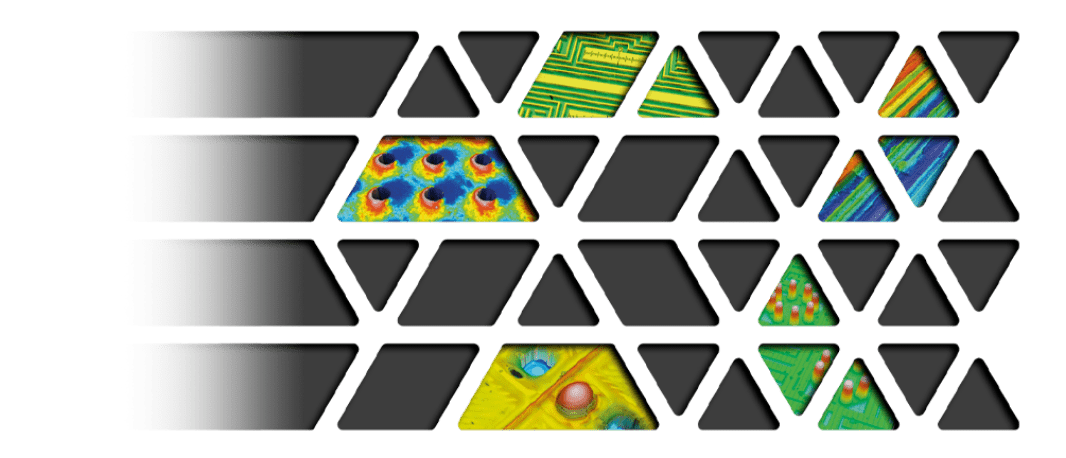

APPLICATIONS

Find your application

The experience gained by Sensofar in specific applications within the advanced manufacturing and consumer electronics markets has allowed us to detect specific needs and tailor individual solutions for each of them. Take a look through our solution pages and find yours!

APPLICATIONS

Find your application

The experience gained by Sensofar in specific applications within the advanced manufacturing and consumer electronics markets has allowed us to detect specific needs and tailor individual solutions for each of them. Take a look through our solution pages and find yours!

HOW IT WORKS

Enhanced 3D optical metrology techniques

Designed as high-performance optical profilers from the outset, some of our systems outperform all existing optical profilers, combining 3D optical metrology techniques all together.

The latest technology together with the most comprehensive software results in a high-level equipment of maximum competitiveness in the market.