The evaluation of texture geometries of automotive engine cylinder liners produced by femtosecond pulsed laser processing

The Manufacturing Technology Centre, located in Coventry, United Kingdom, is an independent RTO founded in 2011. As one of the UK’s High Value Manufacturing Catapults (HVMC), the MTC facilitates the industrialization of innovative manufacturing ideas and manufacturing system solutions. Under the MTC’s Component Manufacturing Technology group, Laser Processing forms a significant part of MTC’s capabilities, covering advanced machining, surface engineering, and material joining.

The S neox optical profiler has been essential to understanding how laser texturing enhances the functional performance of cylinder liner segments.

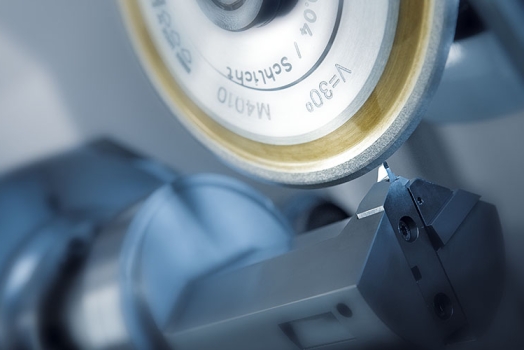

Laser processing enables the development of engineered surfaces by applying textures, producing enhanced functional performance such as surface friction, tactile behavior, wetting properties, and many more. Laser processing using ultra-short pulses durations in the picosecond and femtosecond region allows surface texturing with highly defined micro geometries, edges, and finishes. 5-axis laser processing enables the seamless texturing of three-dimensional components to be carried out having complex profiles.

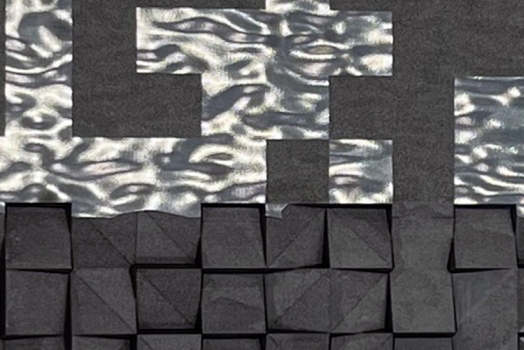

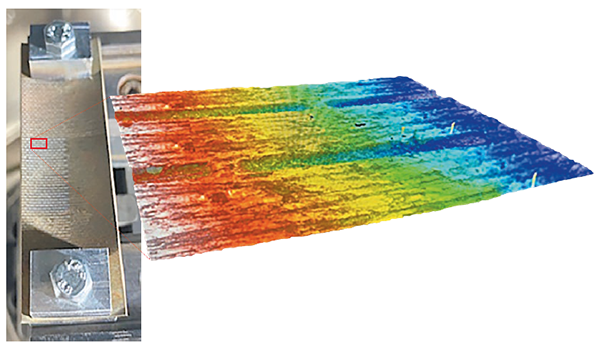

The Sensofar S neox 3D optical profilometer has become an integral part of the development of surface textures at the MTC. In a collaborative experimental study with an automotive company, as part of the European funded Prometheus project, surface textures were developed at the MTC and applied to the curved surfaces of automotive combustion engine cylinder liner segments using a femtosecond laser system. Figure 1 provides an example of a laser textured cylinder liner segment and the texture features using 3-D profilometry.

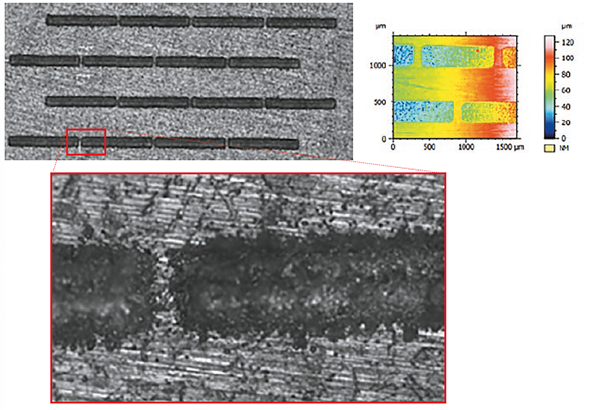

The Sensofar’s integrated confocal microscope and Z axes adjustment enables the complete 2D topography layer to be captured (Figure 2).

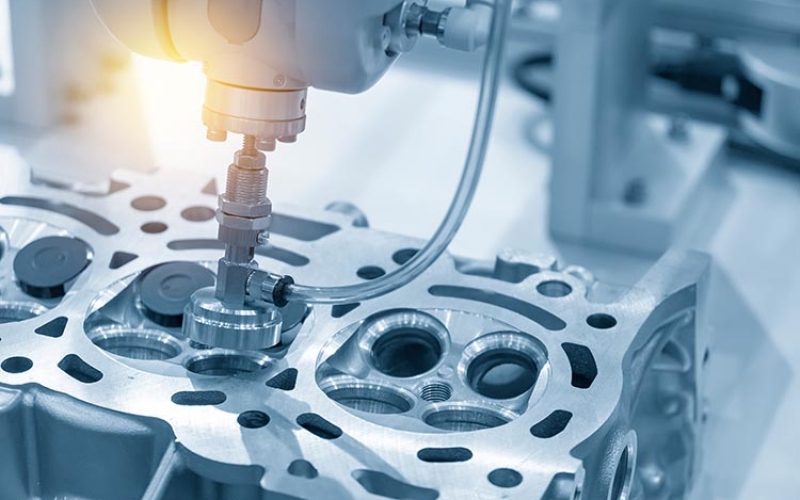

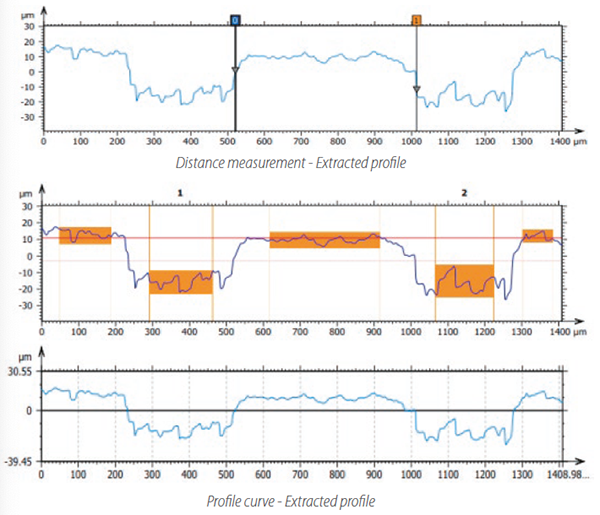

Then using the SensoMAP software, the texture can be analyzed using the capture sequence shown in Figure 3. Firstly, a profile curve of the texture features is extracted from the topography layer (Figure 3a); this allows the critical dimensions of the texture geometry, such as groove width and depth, to be determined. Both the step height analysis tool (Figure 3b) and distance measurement function (Figure 3c) can be used to identify this key data, which enables the analysis of the transition between untextured surface and texture geometry, critical to the indicative frictional performance of the laser textured surface. While distance measurements give the dimension of 2 points on the curve, as manually set by the user, the step height provides the mean height difference giving a more accurate assessment of the change in depth from the laser texturing process.

In this study with an automotive company, the S neox optical profiler has been essential to understanding how laser texturing enhances the functional performance of cylinder liner segments. Specifically, Confocal has proven to be the top performer technology within the three of the S neox. Adding up the analysis software capabilities, we have assessed the frictional performance of the laser-textured surface.

Using the Sensofar and supporting software, we can rapidly evaluate texture designs and develop our laser texturing process to deliver results for our customers.