Guided system

SensoSCAN

Software drives the systems with its clear and intuitive user-friendly interface.

The user is guided through the 3D environment, delivering a unique user experience.

SensoSCAN

Software drives the systems with its clear and intuitive user-friendly interface.

The user is guided through the 3D environment, delivering a unique user experience.

Sample Navigation

An overview tool helps the user to inspect the sample during measurement preparation, check measurement positions before acquisition as well as assist in the automation procedure. Working with high magnification will be easier, as you will know where you are at every moment.

Auto 3D Function

Selecting 3D Auto function, the SensoSCAN software

automatically determines the correct illumination and the appropriate measurement

range, and then performs the chosen measurement type. A high-quality result can thus be obtained within just a few seconds.

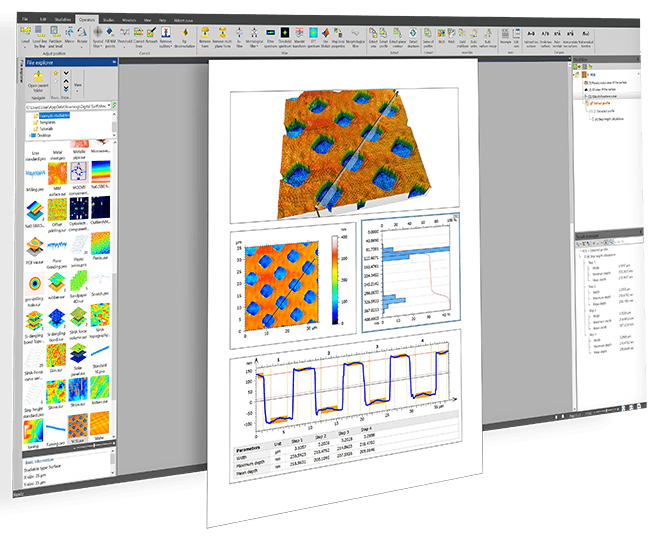

Analysis & Reporting

It is also possible to create analysis templates to apply pre-determined filter and operator configurations to repeated measurements.

And finally, obtain a clear and well-structured report for each measurement, showing the 3D data, a 2D profile and all the ISO parameters.

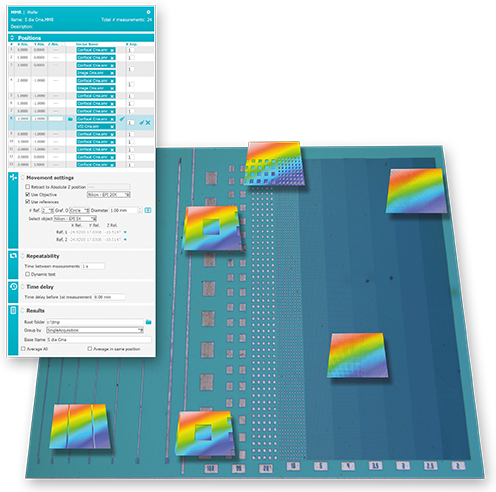

Automated procedures module

The automated procedures module is an easily customizable tool for creating quality control procedures. Creating and running multiple measurement recipes is accomplished using our recipe tool that commands the system to perform several measurements at pre-defined positions. The module combined with tools such as the user manager, sample identification, data exportation, and ‘pass or fail’ tolerance comparison provides all what is need

for QC inspection.

Ready for arrays of samples

The S neox introduces a new functionality that allows to replicate a defined multiple measurement recipe to an array of samples. The multiple measurements will thus be repeated at each sample relative to each sample’s reference point. This simplifies the programming of these recipes, as the recipe is defined only once, and improves the reliability. This will solve long-standing requirements from customers working in QC 24/7.

Ready for arrays of samples

The S neox introduces a new functionality that allows to replicate a defined multiple measurement recipe to an array of samples. The multiple measurements will thus be repeated at each sample relative to each sample’s reference point. This simplifies the programming of these recipes, as the recipe is defined only once, and improves the reliability. This will solve long-standing requirements from customers working in QC 24/7.

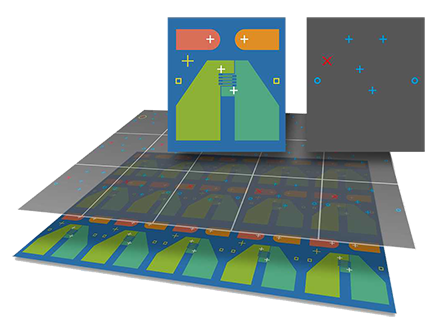

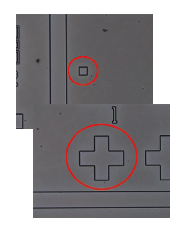

Automatic reference recognition

The S neox now includes automatic detection of fiducials, based on pattern matching algorithms, that enables fully-automated operation without human interaction. What used to be difficult and imprecise, now becomes easy, repetitive, and accurate. The combination of this reference recognition and our automated routines is a step-forward towards industry 4.0.

Up to

500 Mpx

500 Mpx

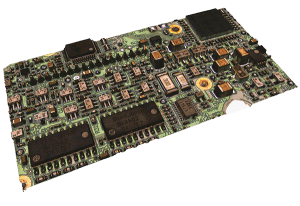

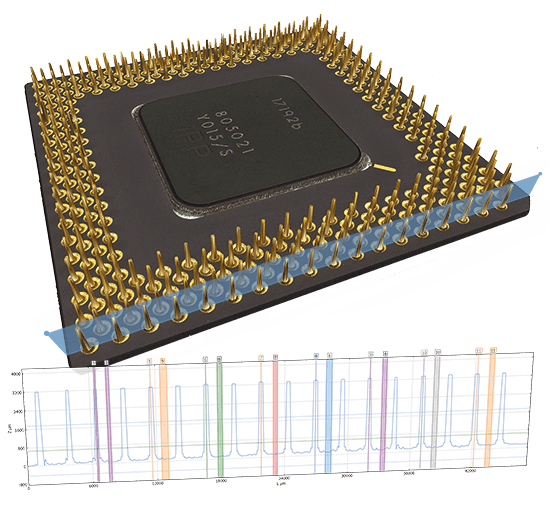

Extended measurements module

SensoSCAN’s extended measurements module allows the user to easily define the measurement layout on the surface by means of the overview image. The area can be automatically cropped to rectangular, circular or ring areas of interest. Wide areas up to 500 million pixels are possible. Several scanning strategies such us autofocusing on each field, or focus tracking to minimize vertical scanning range are available.

Up to

500 Mpx

500 Mpx

Extended measurements module

SensoSCAN’s extended measurements module allows the user to easily define the measurement layout on the surface by means of the overview image. The area can be automatically cropped to rectangular, circular or ring areas of interest. Wide areas up to 500 million pixels are possible. Several scanning strategies such us autofocusing on each field, or focus tracking to minimize vertical scanning range are available.

SensoVIEW

Powerful Analysis Software

SensoVIEW is an ideal software for a broad range of analysis tasks. It includes a comprehensive suite of tools for preliminary examination and analysis of 3D or 2D measurements, allowing roughness or volume calculations and measuring critical dimensions (angles, distances, diameters) with a set of analysis tools.

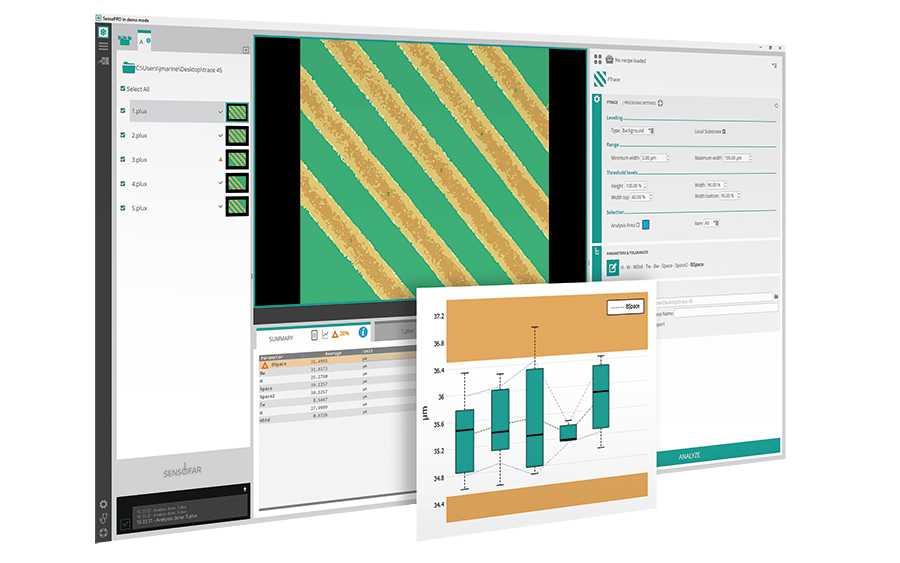

SensoPRO

Rapid Quality Control

It has never been so easy to perform rapid quality control in a production line. Thanks to SensoPRO, a production line operator only needs to load the sample and follow guided instructions to get a pass/fail report. Plug-in-based data analysis algorithms provide a high degree of flexibility. New modules can be easily customized to other industry needs.

SensoMAP

Advanced Analysis Software

SensoMAP, based on Mountains technology from Digital Surf, is an extremely powerful tool for analysis and reporting. SensoMAP software is completely modularly adaptable to customer requirements. Two levels (standard and premium) and several modules are available.