EUROPEAN PROJECTS

Collaborative European projects

Research organizations and leading companies from Europe have joined forces to increase the use of 3D metrology technology in manufacturing. The aim is to help manufacturers unlock the potential of this technology and improve their production processes. By providing necessary tools and resources, European manufacturers can improve their efficiency and reduce waste. With this initiative, they can take advantage of the latest 3D metrology solutions to enhance quality control and ultimately compete better in the global market.

Current projects

FAUSTO project

Sustainable and Secure Autonomous Factory through Deep Technologies

The FAUSTO project aims primarily to drive the development of an autonomous factory that is competitive, safe, and sustainable. To achieve this, it explores the possibilities of Artificial Intelligence (AI) in its most advanced form: Deep Learning (DL), implemented through Edge Computing.

Finished projects

Advanced chemistry and methods to obtain environmental-friendly Cr/P-free conversion COatings on METAls

Finalized: March 2025

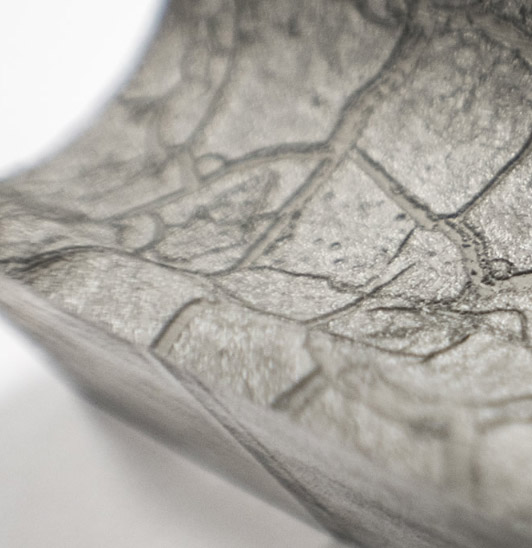

The main goal of this project was to find an environmentally friendly way to improve the performance of surfaces of metals like steel and aluminum alloys, which are widely used in the aerospace as well as more general transportation industries. Sensofar proudly participated in developing and validating Cr/P-free conversion coatings (CCs) for aluminum and steel. These new coatings are based on Zr-Ti formulations and corrosion inhibitors that comply with REACH regulations. The COMETA project aimed to replace traditional Cr(VI)-based treatments for aluminum and phosphate coatings for steel, addressing two critical issues: active corrosion protection and thickness control, both essential for proper paint adhesion and long-term performance.

Traceable industrial 3D roughness and dimensional measurement using optical 3D microscopy and optical distance sensors

Finalized: September 2024

Sensofar participated, providing expert advice on confocal technology. Funded by the EMPIR programme, TRACOPTIC aimed to advance the traceability of optical 3D measurements by developing improved calibration methods and reference standards for optical form and coordinate metrology.

This collaboration helped bridge the gap between research outcomes and practical implementation in precision manufacturing environments.

Industrialising laser functional texturing

Finalized: February 2021

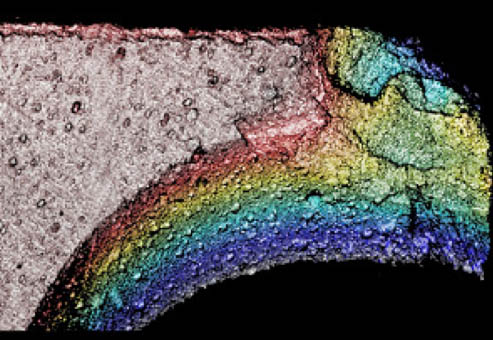

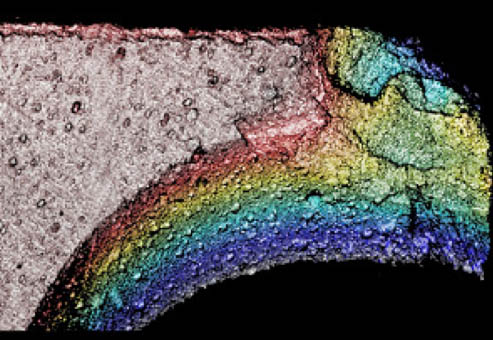

SHARK is a collaboration of research organizations, technology providers and end-users coming together to industrialize laser functional texturing. This market leading consortium covers the full value chain for laser surface engineering and has access to global markets.

Within this project, Sensofar provides a wealth of experience in the field of metrology for these new texture techniques which are being developed. With this collaboration, we are raising awareness of the importance of incorporating optical surface metrology into current production processes.

Midemma zero defects

This project aims at contributing to provide a global solution for the ‘zero defect’ approach in micro-manufacturing, with a focus on the aspects that are specific to micro-manufacturing.

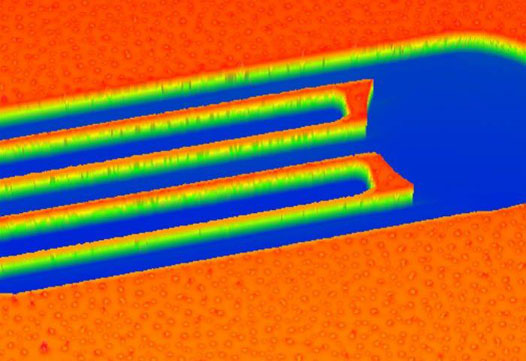

Digiprint by Oxford Lasers

A European project to develop laser-assisted digital fabrication methods for organic electronics, launched by the EU OLAE+ transnational funding scheme.

This project has received funding from the Eurostars-3 joint program with co-financing from CDTI and the Horizon Europe Research and Innovation Framework Program of the European Union.

This project has received funding from the Eurostars-3 joint program with co-financing from CDTI and the Horizon Europe Research and Innovation Framework Program of the European Union.

This project has received funding from the Eurostars-3 joint program with co-financing from CDTI and the Horizon Europe Research and Innovation Framework Program of the European Union.

We are supported by ACCIÓ