Versatile optical system for any inspection environment

Assisted stent inspection

STENT PRODUCTION LINE

Outstanding solution for in-line inspection of stents

The Q six has been designed as a versatile optical system for assisted stent inspection to simplify and streamline stent assessment and approval. This comprehensive solution reduces quality control costs and inspection time, making the task of acceptance faster, easier and more reliable.

Dimensional pass/fail data and classified defect information can be gathered in a short time, enabling the operator to make a fast and reliable decision to either accept or reject the stent.

PRODUCT DEVELOPMENT

Perfect connection between R&D and production, optimizing development cycle

Q six software, SensoINSPECT, is designed to provide versatility to our optical system in any inspection environment. A manual mode is designed to guarantee the required flexibility in R&D and Process Development activities, while an assisted mode is the optimal solution for a fast inspection.

The versatility and ease of use of the system make more efficient the testing cycle of new devices designs during product development, reducing the time-to-market and reducing development costs.

R&D ENVIRONMENT

2D and 3D imaging combination for a complete and assisted stent inspection

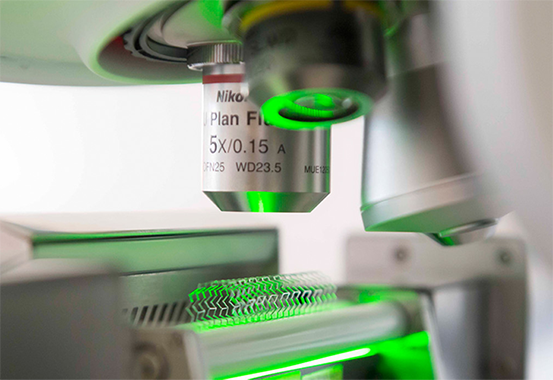

The unique combination of high-resolution imaging and 3D measurements makes the Q six the perfect tool for R&D, comprising a digital microscope, a dimensional measurement system and a 3D optical profiler in an all-in-one sensorhead.

Straightforward navigation between 2D and 3D measurements is possible thanks to Q six’s unique hardware and software combination. It is possible to quickly image the complete surface of the stent and to instantly obtain a 3D image on any area of interest to measure the roughness of the surface or the height of a defect.

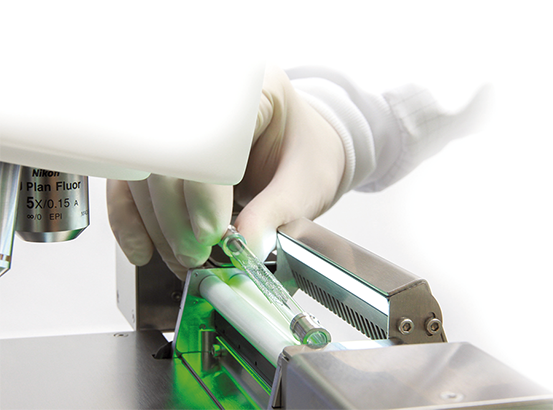

HIGH-ACCURACY POSITIONING STAGE

Automatic positioning at any position of the stent

The roller stage is a modular part of the Q six. Individual stents are manually loaded on the roller stage at the inspection position. All the axes are motorized and controlled by software; including X, Y and Z movement plus 360-degree stent rotation. The user can navigate through manual control or set up a completely automatic inspection routine to scan and analyze all the stent surfaces. Position accuracy of the stage is within 1 micron at any point on the surface of the stent.

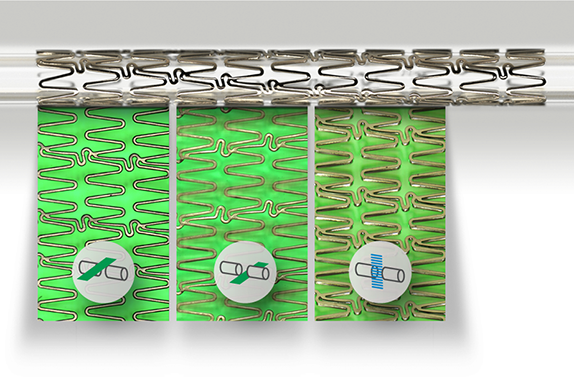

COMPLETE SURFACE INSPECTION

Inspect all stent surfaces with Q six unrolled images

Never seen before, high-quality unrolled images of the outer and inner surfaces and the sidewalls of the stent as well. Images of the outer, inner and lateral surfaces of the stent structure are simultaneously acquired and analyzed at a rate ranging from 5 mm2/s to 20 mm2/s.

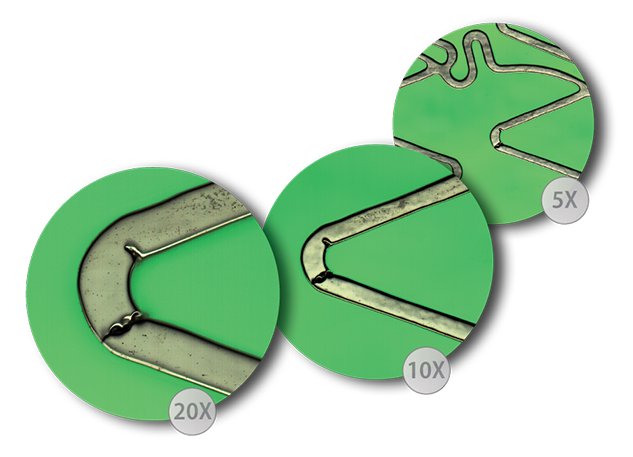

HIGH-RESOLUTION IMAGING

Look at the smallest details of your stents

High NA optical design, premium CF60-2 Nikon objectives, a multi-million pixel imaging array and a unique combination of light sources provide extremely sharp views of the complete stent surface with unprecedented real color, resolution and contrast.