3D-shape measurement of nozzles on the micrometric scale

3D-shape measurement of nozzles on the micrometric scale full article

Ferran Laguarta1, Roger Artigas1, Cristina Cadevall1

1Universitat Politècnica de Catalunya (UPC) Rambla Sant Nebridi, 10, E-08222 Terrassa, Spain.

Proceedings Volume 5457, Optical Metrology in Production Engineering; (2004)

Event: Photonics Europe, 2004, Strasbourg, France

Abstract

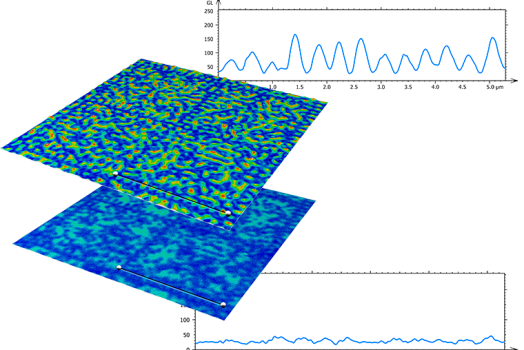

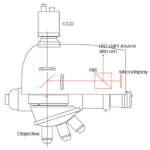

One of the most challenging applications of optical metrology is measuring the shape of the inner surfaces of nozzles such as those of fuel injectors, wiring dies and printheads. A current non-contact solution is confocal laser scanning microscopy (CLSM). However, the inner surfaces of the nozzles behave as though they were optically polished, which gives rise to very weak, backscattered light signals. Therefore, measuring with CLSM is a very slow process and the uncertainty of the results is very high. Moreover, new nozzle designs are moving towards even steeper walls, which means that CLSM may well become useless in the near future. In this paper, we introduce a new method based on a proprietary unfolded confocal arrangement, which uses the light that is reflected onto the inner surfaces and that passes through the nozzle instead of the backscattering signal. The setup and implementation of this new method and the attendant profiling algorithms are explained. With regard to real applications, we focus on measuring the 3D topography of conical nozzles drilled into organic polymer films with excimer lasers. These films are used in the manufacture of the orifice plates, which are attached to the printheads of thermal inkjet cartridges. Fast measurements and accurate results obtained for nozzles of 25 micrometers in diameter and wall angles close to 17º are demonstrated.