Three-dimensional imaging confocal profiler without in-plane scanning

Three-dimensional imaging confocal profiler without in-plane scanning full article

Pol Martinez1, Carlos Bermudez1, Cristina Cadevall1, Aitor Matilla1, Roger Artigas1

1Sensofar-Tech, S.L. (Spain)

Proceedings Volume 11352, Optics and Photonics for Advanced Dimensional Metrology; 113520L (2020)

Event: SPIE Photonics Europe, 2020, Online Only

Abstract

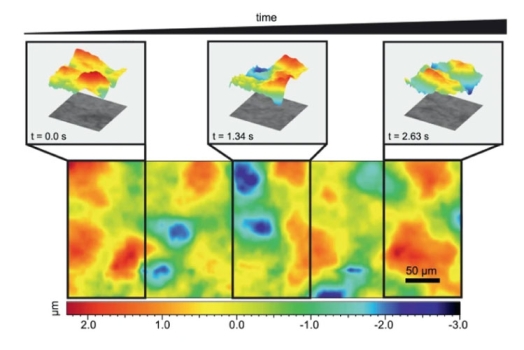

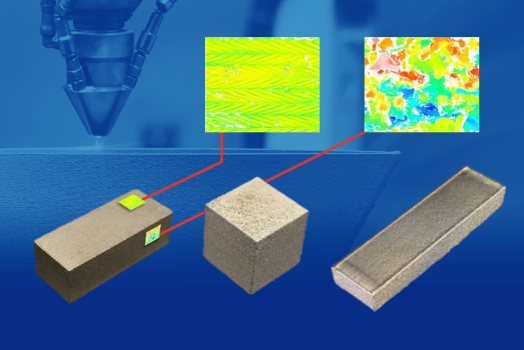

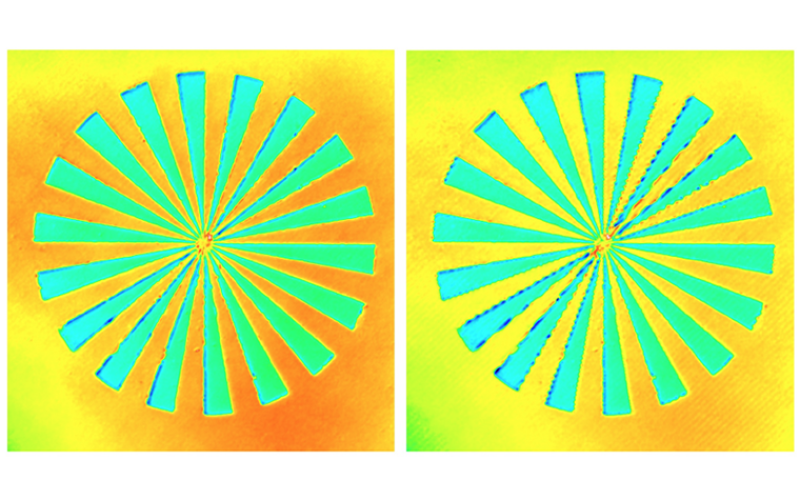

Most 3D metrological microscopes used today require a scanning through the optical axis, which is time consuming. The common techniques are Coherence Scanning Interferometry (CSI), Imaging Confocal Microscopy (ICM), and Focus Variation (FV). If one technique is good for smooth surfaces, it is not for rough ones, while the good for rough is too noisy for smooth ones. Additionally, high local slopes are also dependent on the scattering properties of the surface, making the Numerical Aperture of the objective the most important property of the microscope. Imaging Confocal Microscopy is the best compromise in terms of surface application range (from smooth to rough), high local slopes on shiny surfaces, highest numerical aperture and highest possible magnification. Unfortunately, any kind of Confocal microscope today (laser scan, disc scan or microdisplay scan) requires an in-plane scanning to build up the confocal image in addition to the vertical scan, increasing the total measuring time in comparison to CSI and FV. This is against the needs of quality control in production environments, where scanning speed must be as short as possible. In this paper, we use a Microdisplay Scanning Microscope for obtaining the confocal image only relying on a single image per plane. We use a structured illumination to project a desired pattern onto the surface with a very well-defined frequency and direction. By means of the Hilbert transform, we digitally shift the projected pattern one or many times to recover the bright field and the optical sectioned images. This new method reduces significantly the measurement time, simplifies the overall cost of the system and eliminates the maintenance of scanning devices, while maintaining the optical sectioning properties of each plane. We also studied the performance of the resulting topography in terms of system noise, accuracy, repeatability and fidelity of the surface using different methods to obtain the confocal image. Finally, we also compared the results with true confocal results and with other techniques that require a single image per plane, such as Active illumination Focus Variation (AiFV).